Meeting the HACCP standard with GRP surfaces

A constant temperature-controlled system that meets HACCP hygiene standards is required for processing and transporting foodstuffs. Cooling superstructures with roofs and side walls made of glassfibre-reinforced plastics (GRP) create the ideal conditions on the surfaces.

Companies that handle food must monitor and document their hygiene standards in line with the HACCP concept. HACCP means: hazard analysis and critical control points; hazard analysis and critical control points. Preventative, standard measures taken by employees are included in this, as are the materials used in environments where food is handled. GRP also have a role to play in disease preventions and hazards - in either direct and indirect contact with food.

Since 2006, only foods that have always been handled in a HACCP-compliant manner can be traded within or imported into the EU. This applies to processing in companies and also to transport, storage and sale, and it has to be documented. Traditionally, this involves general hygiene measures such as cleaning surfaces, incoming goods inspections and pest control, as well as the materials with which food is wrapped or even comes into contact. Within the European Union, it is not obligatory to have HACCP certification, but Regulation 852/2004 requires' that one or more permanent procedures based on HACCP principles is established, implemented and maintained'.

Hygienic environments in cold stores and refrigerated transporters

In the context of carrying out risk assessment of the internal walls of cold stores and transport companies, TÜV Süd has defined specific criteria for HACCP certification. These include the testing of the materials used for food safety for direct long-term contact, in accordance with the German Food, Commodities and Feed Code (LFGB) §64.

The Solution

LAMILUX HACCP Gelcoat for Plastic Sheets - to meet the HACCP standard an achieve certification with GRP surfaces: LAMILUX HACCP Gelcoat is also suitable for GRP that come into direct contact with food, and for the immediate environment. These include standard materials for the lightweight construction of transport vehicles as well as exceptionally strong, impact-resistant materials.

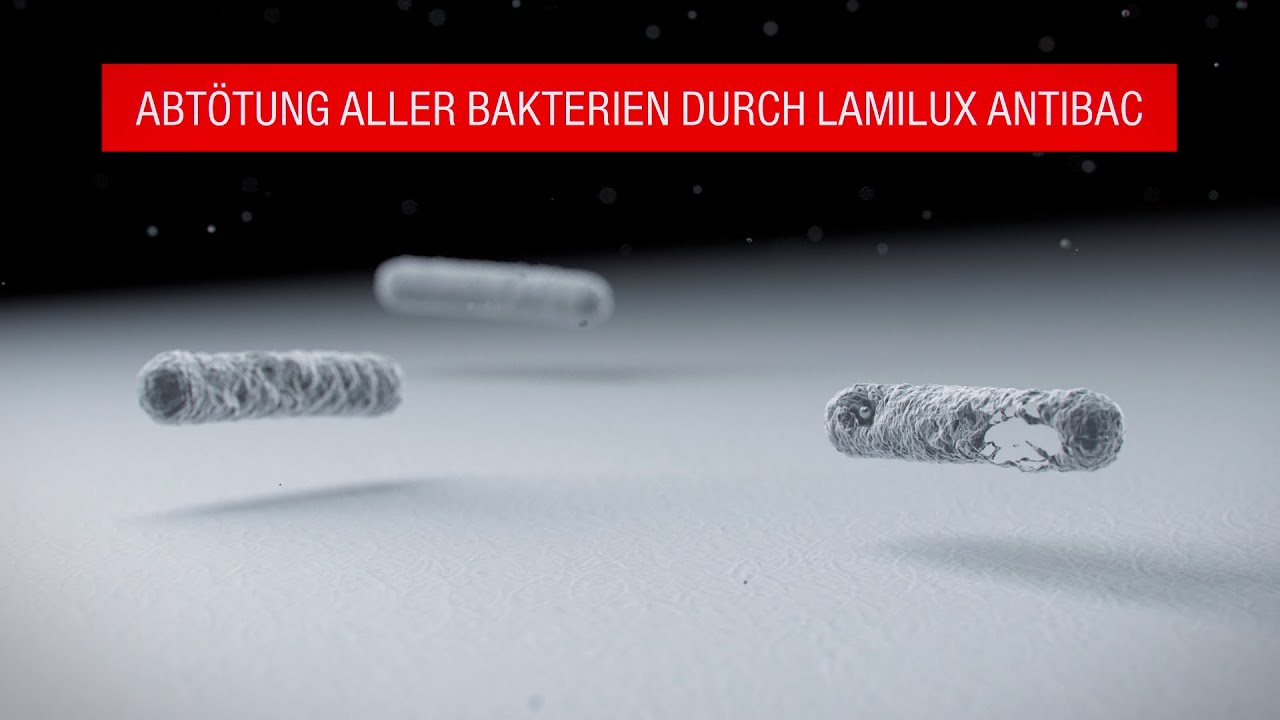

Hygienic killer: Surface actively kills germs and bacteria

In addition, you can also integrate the AntiBac function into LAMILUX products with HACCP Gelcoat. Nanosilver particles in the composite actively kill 99% of all bacteria and even multi-resistant germs on the surface of the plastic sheet.